Brew Smarter: The Ultimate Cost-Effective IPA Calculator for Craft Breweries

✅ Sample Version (no sign-up required)

Estimate revenue from multiple container sizes (pints, crowlers, flights, etc.)

View gross profit and gross margin per batch

Break down and itemize:

Ingredient costs (with optional scrap/waste %)

Labor by task and staff role

Overhead costs allocated to the batch

Forecast sales volume by container type and ensure it matches batch yield

Built for taproom-focused or wholesale production planning

🔒 Get the Full Version (free with newsletter sign-up)

Everything in the Sample Version, plus:

Compare up to three IPA recipes side by side

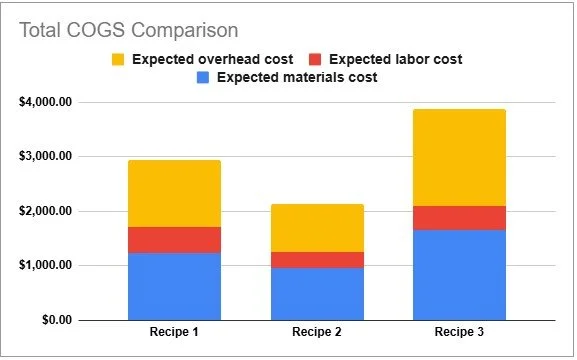

Automatically generate charts for:

Total cost breakdown by category (ingredients, labor, overhead)

Gross margin and cost per oz across all recipes

Sensory and quality scores by recipe (radar/spider chart)

Track and compare sensory and drinker experience metrics

Evaluate operational performance across recipes

Get a clear, visual COGS and margin comparison between recipes

Quickly identify which IPA is the most profitable, efficient, and customer-loved

Use for launch decisions, quarterly reviews, or cost-driven retooling

The full version will arrive via link at the email you entered above. You’ll also get an occasional newsletter with tools and blog posts. Unsubscribe anytime.

Who is this IPA recipe calculator for?

This spreadsheet is for craft brewery owners and taproom managers that want to maximize profit on every IPA they brew. It’s for breweries that are looking to fine-tune their recipes, reduce costs, and compare profit margins across different recipes.

What does this IPA recipe calculator help them do?

Calculate total cost of ingredients, labor, overhead, and waste

Break down expected sales by container size (pint, tulip, crowler, etc.)

Determine gross profit and margin per batch

Compare three recipes side by side for better decision-making

When should you use this IPA recipe calculator?

When developing a new IPA (or any other style!) recipe

Before scaling for distribution

When pricing your beers or contending with cost increases

Where does this IPA recipe calculator fit into your brewery’s operations?

At the recipe development stage, to estimate profitability before brewing a single batch

In financial review meetings, to estimate recipe performance and costs

Alongside your POS and accounting software, giving you financial and operational insight those pieces of software miss

Why does this IPA recipe calculator help your brewery?

Reduce waste and overuse of expensive ingredients and materials

See the impact of changes in ingredients and labor in real-time

Make smart pricing decisions to hit margin targets

Justify cost savings to your team or partners with solid numbers

How to use the IPA recipe calculator

This worksheet gives you a clear picture of your IPA recipe's profitability—from batch yield to gross margin. Use it to test new recipes, plan production, or dial in pricing.

1. Set your batch details

At the top of the worksheet:

Enter the name of your IPA recipe

Input the expected batch size in barrels (BBL)

Enter the ABV for this particular recipe

Enter the total annual BBL you brew

2. Forecast your sales by container type

In the Expected Batch Sales section:

List the container sizes you expect to sell (tulip, pint, crowler, etc.) and the ounces per container

Enter the price you expect to sell each container for

Input how many of each size you plan to sell

The spreadsheet will automatically calculate expected oz sold and expected revenue. The spreadsheet will flag you if it exceeds your expected batch yield.

Use POS reports, packaging logs, or past sales information for accurate estimates.

3. Enter your ingredient costs

In the Batch Ingredients section:

List each ingredient (grain, hops, yeast, packaging)

Enter the quantity used in a batch, unit of measure, and cost per unit

Optionally, include a scrap amount for ingredients lost to waste

The sheet calculates your total ingredient cost, including loss due to scrap.

Pull numbers from your inventory system, invoices, or supplier quotes.

4. Log your labor steps and costs

In the Batch Labor section:

List major brewing and packaging steps

For each step, input the estimated labor hours and hourly rate (include taxes, benefits, and all other related costs)

Total man-hours and labor cost will be automatically calculated. It will also calculate a weighted-average hourly rate.

Use shift logs or time-tracking software to estimate labor hours per task.

5. Add any overhead or waste costs

Use the Batch Overhead section to input fixed costs like utilities, rent, and equipment depreciation.

6. Compare quality, efficiency, and margin across recipes

Use the Recipe Comparison sheet to evaluate all your IPA recipes side-by-side. You’ll be able to compare:

Gross margins

Forecasted sales volume

Perceived sensory traits like mouthfeel, bitterness, clarity, and body

Operational factors like labor time

The chart visualizations on this sheet will help you quickly see which IPA offers the best mix of profit, efficiency, and drinker appeal.