Brewing Cost-Effective IPAs (or Any Other Style of Beer)

What are the obstacles to brewing profitable IPAs?

IPAs can be expensive to brew

IPAs are on every brewery's menu, and many people come to breweries looking exclusively for IPAs, so they’re an important part of your lineup. But they’re often made with expensive ingredients. The temptation to make your IPA stand out can lead to using higher quantities or premium ingredients—without fully realizing how it affects your costs.

Why is this a problem?

Premium hops and specialty malts drive up your input costs. These ingredients are often imported and priced unpredictably. If something is trending, competition for it can spike prices even higher.

Everyone assumes more of these premium ingredients equals better flavor. That assumption can lead to overloaded recipes—without solid data to show whether the extra ingredients are worth it in terms of flavor or cost. You might just be inflating your costs unnecessarily.

No taste analysis or yield testing is done. Most breweries aren’t aiming for the minimum effective amount of ingredients. Like salt in food, more doesn’t always mean better—there’s a point of diminishing returns.

No cost-per-SKU analysis. If you don’t know exactly what it costs to brew a specific beer, inefficiencies can go unnoticed. That’s when profits slip through the cracks. A single, generic “cost of goods sold” line isn’t enough.

You (the brewer) don’t have the tools or time to analyze your costs. Totally understandable—you’re busy doing what you love: brewing. But you still need someone to help get the data into a spreadsheet so you can gain real financial clarity.

Your brewery doesn’t use resources efficiently

Beer takes more than just ingredients. It takes water, energy, CO₂, and other resources. These are often hidden costs—because they aren’t tracked or tied to individual batches or SKUs. On a single batch, the waste might seem small. Over time, though, it adds up.

Why is this a problem?

You can’t manage what you don’t measure. If you don’t track how much water, energy, or CO₂ goes into each barrel, you have no idea if those costs are minor—or eating away at your margins.

You defaulted to someone else’s process. You probably learned from someone who didn’t manage resource use either, so it never occurred to you. You likely picked up great habits—but probably a few costly ones too.

Your focus is on volume, not efficiency. Whether directly or indirectly, your team is rewarded for output, not conservation. Yield and efficiency often aren’t prioritized—or incentivized.

Technical solutions are underused. CO₂ recovery, nitrogen generation, flow controls—they exist, but maybe you haven’t adopted them because of cost, habit, or just not knowing what’s available.

Nobody owns resource efficiency. As the owner, it ultimately falls on you. But if you're not aware of how waste impacts your costs, nobody’s managing it—and it stays invisible.

Your beer pricing is out of whack

Your beer is probably great. But if it’s priced too high, it won’t sell. If it’s priced too low, it’ll sell at a loss. Pricing is part art, part math. It shouldn’t be driven by cost alone—but you still need to understand your costs to price effectively.

Why is this a problem?

Big national brands shape price expectations. They benefit from economies of scale and can price lower than you can afford to. But your customers still compare your price to theirs.

Your recipes weren’t built with a price target in mind. You probably build for flavor first—then figure out what price you need to charge. Flip that: start with a cost target, then build the recipe.

Pricing is based on gut, not data. Your instincts matter—but they work best after you’ve looked at the numbers. Start with the data, then layer in your judgment.

Distributors and retailers squeeze your margins. Distribution is a volume game—low margins, high throughput. Retailers want your beer priced close to the big brands, but you’re still working with the same higher costs.

You don’t have a tiered or portfolio pricing strategy. Most brewers don’t. Everything ends up priced the same way, regardless of cost structure or target customer. You need intentional margins across different SKUs.

How should you have been brewing IPAs all this time?

Knowing how you would have done things—with the benefit of 20/20 hindsight—helps you know what to do better going forward.

You crafted a recipe with pricing and margins in mind

Starting at the end and working backward. You knew what you were going to package this particular beer in. If it was going to be served in pints and tulips in your taproom, or distributed in four-packs of 16 oz cans.

Knowing the packaging size—and therefore the cost to package it, plus how much beer goes into each—helped you come up with a target price point for each package size. Needless to say, if you were planning to distribute this beer through a wholesaler, the price you focused on was your selling price to them, not the retail price the customer pays.

Once you knew the price, you continued to work backward to determine what gross margin you wanted to make for each package type. That margin was higher on taproom pours (like tulips) than it was on bulk packaging like 12 oz cans. You knew that, generally, the higher the volume you sell, the lower the gross margin you’re willing to accept. Of course, it doesn’t need to be a massive difference—but it should reflect your pricing strategy. You also knew that premium offerings typically have higher margins. More standard beers, lower margins.

Target cost = target price × (1 - target gross margin %)

Example: for a pint, $7 × (1 - 70%) = a target cost of $2.10.

Since you knew your gross margin, then you knew your cost ceiling. You subtracted the cost of packaging and labor, and were left with the cost of the beer itself. From there, you could extrapolate based on how much you planned to brew, and then knew the total batch cost you needed to stay under to hit your margin targets.

Example:

Planned batch size of 18 bbl = 558 gal = 4,464 pints

$2.10 × 4,464 = total target cost (not accounting for loss) = $9,374.40

From there, you reverse engineered your recipe. Decided how much you could spend on hops, malt, labor, packaging, etc. You also didn’t forget the cost of resources like water, energy, and CO₂…

You optimized recipes with testing and sensory analysis

This whole process is a feedback loop. Quality matters, but you wanted to maximize quality within cost constraints.

Ideally, you would have done this on a small scale before moving to full production—just to dial in your recipe. Substituting hops, malt, or other ingredients with lower-cost alternatives that still meet your quality standards.

Taste testing is critical. So, you determined the minimum amount of each ingredient needed to meet your expectations. Especially those premium ingredients—particularly the point of diminishing returns in terms of aroma, flavor, and appearance.

This took some tinkering—and yes, some taste testing—to find the most cost-effective version of the recipe that still delivers for you and your customers. But the payoff was huge—a delicious beer that fits a particular profile on your menu that you can be sure will be profitable.

You analyzed your production metrics from the get-go

From day one, you would’ve had basic flow meters installed for water, CO₂, gas, and electricity. That way, you’d know roughly how much you’re using per batch.

Then you’d combine that with what you’re probably already tracking—ingredients, labor, loss, etc.—and keep it all in an evolving spreadsheet of batch data.

Over time, that spreadsheet becomes a powerful tool. It helps you spot inefficiencies and tighten up your processes. Eventually, you’d set internal benchmarks and hold yourself (and your team) accountable for both cost control and resource usage.

What can’t happen when you’re brewing your IPAs

You've avoided the worst-case scenarios so far—hopefully. But let’s talk about what absolutely can’t happen so we can steer clear of it.

Selling beer at a loss

Anyone with basic business sense knows you can’t sell at a loss. Not for long, anyhow. But where brewers get tripped up is not fully understanding all the costs involved in brewing and selling beer. This post focuses mostly on the cost of goods sold (labor, materials, and overhead), but don’t forget—you also need to cover everything else: sales, general and administrative expenses, etc.

Costs can creep up on you. Ingredients, labor, utilities—they all tend to increase over time while your prices could stay flat for years. If you’re not regularly analyzing your costs, you might end up selling at a loss without even realizing it.

Also, using a distributor is going to squeeze your margins. You’ve got to make sure you’re hitting gross margin targets so the volume is actually worth it. Every brewery has fixed costs, and those need to be covered before you can even break even.

Dilution of the brand

So far, we've talked about avoiding ingredients that are more expensive than necessary. The key word there is necessary. You’ve still got to maintain your quality standards—or customers will leave. It’s about finding that sweet spot: meeting expectations without overloading your beer with unnecessary costs.

Things like flavor, aroma, mouthfeel, and presentation still matter. They're the reason people go to craft breweries in the first place. If they wanted bland, watered-down beer they would go to a convenience store.

Also, consider the impact of repeated changes to recipes, packaging, or pricing. These changes can create uncertainty. Sure, novelty is part of the charm of craft brewing—but consistency matters too. Inconsistency can lead to bad reviews and declining customer loyalty.

Brewing inefficiencies and waste

Inefficiencies in brewing and packaging drive up your cost per batch. Wasted resources—like excess water, CO₂, or energy—add cost to every ounce of beer you sell.

Another issue is overproduction. If beer sits too long, it spoils or loses its appeal. Then you’re forced to discount it, which cuts into your margins and profits.

And don’t underestimate how much poor systems and planning can impact your team. People feel good when they’re working efficiently and their time is well spent. Sloppy systems cause burnout, errors, and eventually staff turnover.

What is your vision of brewing IPAs?

Okay, so now you know what you should’ve been doing—and what you absolutely need to avoid. Time to crystallize a vision of what you want to achieve when brewing your IPAs. Your vision is your own, but here are some suggestions…

Is it a high-margin, high-quality IPA?

It’s pretty safe to say you’d like all your beers—not just IPAs—to be both profitable and desirable. That means there’s strong demand for them, and every time you meet that demand, you put a nice chunk of change in your pocket.

So what does that look like? First, your flagship IPAs should have strong margins. These are the beers you’ll serve day in, day out, year after year. You need a strong grasp of what your costs are and what your target margin should be.

That means using ingredients that maximize flavor per dollar—and limiting unnecessary additions unless they truly enhance the customer’s sensory experience. Anything you put in that comes with a premium price tag must earn its keep.

You also want to meet (or exceed) quality expectations without making production a hassle. Start simple. For new recipes, keep them clean until you find the best balance between flavor, cost, and efficiency.

Pair that with solid marketing—labels and messaging that catch the eye and get people to try your beer—and you’re well on your way to that sweet spot of high margins and high quality.

Is it a brewing system that works efficiently?

As always, quality is king. But just because you make high-quality beer doesn’t mean production costs and waste should go unchecked.

If you’re using software like Ekos or Ollie to track costs—great. But are you pulling that data into a spreadsheet and actually analyzing it?

Break it down into understandable units.

How much CO₂ and water are you using per barrel?

How much loss are you incurring from transfer, spoilage, or overproduction?

Is your process smooth, or is it bogged down with obstacles and downtime?

Are you using SOPs (standard operating procedures) for every step?

If you had to hire someone new to brew tomorrow, would they have a rock-solid process to follow?

Does your staff know how to spot inefficiencies? Have they ever brought one up and you brushed it off? Do they have a continuous improvement mindset?

And while you’re at it, build a few simple dashboards.

Track things like:

Utilities per barrel

Labor hours per batch

You can’t manage what you don’t measure.

Is it a perception of quality and value by the customer?

You can practically write your own check if your brewery is seen as both high quality and a great value. Customers will rave if they feel like they’re getting epic beer at a fair price—even if that price is a little higher than your competitors’.

That’s where transparency comes in. Talk about what went into the beer. For example, the specific hops you used to deliver intense flavor without excess bitterness.

Also, since you’ve nailed down costs and margins for your flagship beers, maybe you can price them a bit more competitively. Then sell small-batch or special releases at a premium.

You can increase perceived value with smart bundling. Think: a flight plus a to-go 4-pack deal, or something similar.

And don’t hesitate to highlight the work you’ve put into the brewing process. Show off your efficiency and sustainability efforts. Let people know you’ve brewed with purpose.

That kind of messaging builds goodwill—and makes your customers feel warm and fuzzy, like they’re part of something bigger.

Where can you get help brewing cost-effective IPAs?

You don't have to go this alone. There are people and tools out there that can help you dial in your IPA recipes—along with everything else you brew—so they taste great and stay profitable.

Brewing industry organizations and networks

The Brewers Association offers benchmark data, cost studies, margin insights, and tips on best practices ($230 annual membership required). This can give you a solid idea of what other brewers are doing when it comes to costs and margins on their IPAs. It might also highlight opportunities to cut costs without sacrificing quality.

The Craft Brewers Conference includes workshops, expert panels, case studies, and peer networking. It’s a chance to pick up real-world tips from brewers who’ve already done what you’re trying to do—no theory, just practical knowledge. Plus, since most attendees are from different markets, people might be more open and willing to share ideas. You can even contribute your own strategies around improving margins or simplifying your brewing and packaging process.

Local brewers’ guilds (E.g., the Florida Brewers Guild) or co-op purchasing groups can also be incredibly helpful. Participating in one could give you access to group buying power and volume discounts on raw materials—without compromising ingredient quality. It’s also a great way to share ideas and solve production challenges together. Buying in bulk lowers your per-unit cost (even for premium ingredients 👍🏼).

Brewing software and other tools

Leverage the power of tech. You’re probably already using some of these tools—just make sure you’re getting everything you can out of them to better understand costs, improve production, and turn your data into action.

Ekos, Ollie, Beer30, and similar tools are brewery-specific software that help you track ingredients, batch costs, and production in real time. They make it easier to run cost-per-barrel analysis and spot waste. That’s exactly the kind of visibility you need to keep your flagship IPAs running with solid margins.

Then there’s QuickBooks and good old spreadsheets. Maybe your bookkeeper or accountant handles this stuff, but make sure you’re getting useful reports from them. Your bookkeeping software should give you the info you need to build financial models and forecasts. When you combine those numbers with a spreadsheet, you can calculate cost per unit and breakeven points quickly and clearly.

Don’t sleep on SOP (Standard Operating Procedures) software, either. Once you’ve nailed that recipe that balances quality and profitability, SOPs make sure every batch delivers the same consistent product. Pair those with sensory analysis templates, and you can cut variability, ensure quality, and maintain cost-effectiveness every time.

Expert consultants

If all this sounds overwhelming, bring in some help. A good consultant can help you boost efficiency, improve quality, and control costs.

Brewery consultants or process engineers can map out your workflow and help you identify where waste is hiding and where yield can be improved. You probably already have a sense of where things feel clunky—but having it laid out visually (on paper or screen) often makes it clearer. A fresh set of outside eyes might also spot inefficiencies you’ve grown blind to over time, especially in areas where processes have gotten messy or bloated.

Ingredient supplier reps are another great resource. They can help you optimize hop blends, suggest malt substitutions, or recommend cost-effective alternatives without sacrificing flavor. They work with lots of breweries and get constant feedback on what works. Take advantage of that insight. It’s a smart way to stretch your dollar without compromising impact.

Your local economic development office might also have something to offer—things like free or subsidized business audits, grants for sustainability efforts, or even incentives for equipment upgrades. Here’s an example from the Wisconsin Economic Development Corporation. These programs can help you improve your margins while also giving you a marketing angle (greener brewing = good PR).

Why will your IPAs be okay?

Let's end on a positive note! You're moving in the right direction, and your brewery is going to be okay no matter what.

Your brewery is resilient

Consumer trends are always changing. That's just part of the business. Every brewer hits rough patches, whether it’s unexpected jumps in ingredient prices, equipment breakdowns, or staff turnover. But you already know these things happen. Your attitude, perspective, and the actions you take determine how much they affect you. Hopefully, you see these as temporary hiccups and very solvable problems.

If you reflect back, I’m sure you’ve already overcome plenty of hurdles. Starting up wasn’t easy. And if you’ve been open at least five years, you made it through the COVID-19 mess. Then came the supply chain disasters that followed. So developing a profitable, great-tasting IPA should feel like a walk in the park by comparison. Plus, dialing in your recipes now will make your business stronger for whatever comes next.

Asking tough questions like we did in this post should spark some valuable insights. For instance:

– Which of your beers are actually driving your margins?

– How much are you wasting during the brewing process?

– What have you been spending money on that wasn’t really essential?

Even if things have leveled off this year in terms of sales or profitability, you’re setting yourself up for strong growth in 2025 and beyond.

Small changes at your brewery can have big impacts

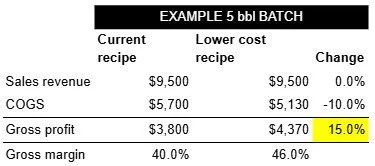

The changes we’ve talked about so far don’t have to be massive to make a real difference. For example, if you can cut your ingredient costs by 10% (while keeping quality high), that translates into a 15% margin boost on your IPA.

Projects like CO₂ reduction or water reuse may require short-term investment. But long-term cost savings can easily make them worth it. Efficiency doesn’t necessarily mean compromise. The systems you put in place—SOPs, batch tracking, etc.—should give you peace of mind, not make you cringe.

Buying raw materials at lower costs with the help of a co-op, or reducing labor hours can move the needle quickly—and that should energize you. Just make sure whatever you implement actually makes an impact. Don’t waste time on actions that look good on paper but don’t move the business forward. Avoid vanity metrics.

Your brewery is creative

Margins are tight for everyone right now. That’s why this is your chance to get intentional with your brewing. Skip the gimmicks. Focus on creating a beer that tastes amazing and is cost-conscious. Your customers will appreciate it—especially if you can price it fairly.

Use your story in your marketing. Show people how intentional you are in brewing your beers. That communicates how seriously you take your craft—and reinforces your commitment to quality. A powerful message for your brand.

Yeah, it’s a little cliché, but challenges do create opportunity. Why not explore hybrid beers? Or lean into the growing interest in low-ABV options? Not non-alcoholic, necessarily—but something more sessionable that people can feel better about drinking.

Whatever it is, let these hurdles help you to stand out—and turn adversity into something great.